Sex Doll in Use

Wound Repair on TPE Sex Doll and Silicone Sex Doll: Bonding and Filling Products

Table of Contents

I – INTRODUCTION

This article describes the different products and methods used to repair wounds with or without loss of substance on TPE and silicone. It will focus on room-temperature bonding. Repair methods using heat will only be mentioned, and may be the subject of another article. The focus will be on TPE-to-TPE and silicone-to-silicone bonding. TPE or silicone bonding to a different material will only be discussed for eyelashes and nails.

The actual methods of applying the products will be mentioned but not detailed. For this, please refer to the numerous articles, posts and videos on these subjects. The aim of the present work is to list the various products for bonding and filling TPEs and silicones, to report on their properties, and to test them.

II – NATURE AND STRUCTURE OF TPEs AND SILICONES

1) TPEs

Thermo-Plastics-Elastomers is a generic term covering a wide variety of polymerized organic materials with common physico-chemical properties. The main properties of TPEs are elasticity and stretchability, with full return to the original shape (at room temperature and excluding any physical or chemical degradation). Another characteristic is thermoplasticity, i.e. the ability to melt at relatively low temperatures: from 40-50°C, TPE starts to become sticky and deform, then melts at around 100°C. This property can be used to repair wounds with a hot iron, but in everyday situations, TPE dolls should not be exposed to heat.

Without going into chemical details, it should be noted that TPEs are a family of complex polymers (assemblies of identical molecules), composed of a thermoplastic polymer (products commonly referred to as “plastics” in the broadest sense) and an elastomeric polymer (products often referred to as “rubbers” in the broadest sense). The components are either mechanically mixed, or linked by chemical bridges called “blocks”.

The most common TPEs are those with styrenic blocks. It is difficult to know which types of TPE are used in the manufacture of lovedolls, but indirect indications can be found on certain specialized sites (source: Hitop Industrial):

“For products that require a soft touch, such as toys, handles, or portable electronics, Styrenic Block Copolymers (SBCs) are an excellent choice. SBCs provide a rubber-like texture combined with good transparency, making them ideal for parts where aesthetics and user comfort are important.”

2) Silicone(s)

Silicones are chemically manufactured on the basis of inorganic polymer chains composed of silicon and oxygen atoms. The silicones used in the manufacture of lovedolls are composed of these polymer chains linked to organic radicals containing carbon. They thus acquire the physical properties of elastomers, notably stretchability and elasticity. Additives are added during the manufacturing process, in particular lubricating substances. The silicones used in the manufacture of lovedolls are less chemically diverse than TPEs, and from this point of view constitute a more homogeneous family. Their main characteristics are flexibility, plasticity and insensitivity to heat, up to 150 or 200°. This makes silicone dolls insensitive to everyday temperatures, including exposure to the sun, in a car interior or during heatwaves – all problematic and risky situations with a TPE doll.

3) Important point: solvents

TPEs are sensitive to many chemical substances:

- Oil is not a chemical solvent for TPE, but given the high oil content of the TPEs used in lovedolls, it acts as a physical solvent: when the TPE becomes saturated with oil, its structure tends to loosen, then break up;

- Acetone strongly degrades the TPE on prolonged exposure, destroying the oily charge, but does not dilute the material homogeneously;

- Aromatic solvents such as xylene and toluene are true solvents for TPEs, melting the material on contact with them without chemical interaction or irreversible degradation. After volatilization, the TPE takes on a semi-solid, repolymerized appearance again.

3M94 primer is a blend of different solvents, including xylene. As such, it can be considered a solvent for TPEs.

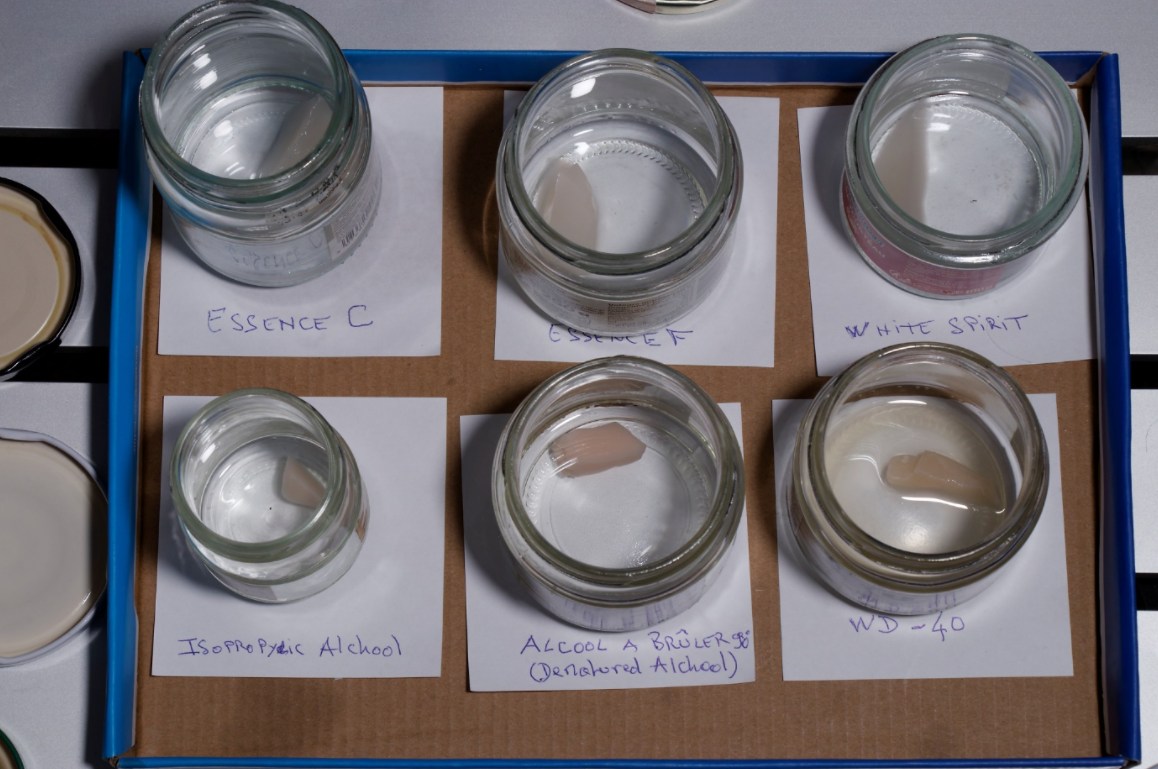

Silicones are not very sensitive to common solvents, due to their mineral composition and hydrophobic sealing properties. The most frequently cited solvents for silicones are mineral spirits (C and F), acetone (but ineffective in my experience), and isopropyl alcohol.

Test results

After several days’ immersion of the samples in closed bottles, these tests all proved negative, as the immersed fragments had not undergone the slightest onset of dilution, with the exception of the sample soaked in WD40, which showed the beginnings of dilution.

At this stage and after these tests, it is therefore not possible to cite an effective solvent or diluent for the silicone in the samples tested.

III – WHAT IS BONDING?

The mechanisms involved in bonding are complex. In all cases, bonding is the interposition of a material between two parts, which will adhere to these parts and solidify, making the whole resistant to the disbonding forces applied to it. Bonding differs from fusion welding, in which a chemical or physical agent (heat) causes the two parts to adhere without the addition of material. As we shall see, when it comes to polymers, particularly TPEs, the distinction is not always clear-cut. This article will therefore use the term “bonding” to cover all adhesion processes, whether total or partial welding is involved.

Four main types of adhesion mechanism are described (source: 3MFrance):

- Chemical adhesion: Chemical adhesion occurs through molecular contact with the substrate surface. This is the most powerful adhesion mechanism, with bonds developing between the functional groups of the adhesive and atoms or molecules on the substrate surface.

- Mechanical anchoring: occurs when the adhesive penetrates the pores of the substrate surface. Anchoring provides a physical barrier to crack propagation at the interface. It also serves to increase the surface area, thereby increasing the degree of complete contact between adhesive and substrate. Liquid adhesives settle easily when applied to the substrate before drying or curing.

- Diffusion adhesion: occurs when the adhesive polymer is able to penetrate and mix with the substrate. An interface is created with entangled polymer chains linking the adhesive and substrate. This mechanism is common in assemblies composed of low surface energy materials that are difficult to bond, such as polypropylene.

As a reminder, there is also electrostatic adhesion, which occurs when the glue-charged surface is attracted to the oppositely-charged substrate, which is most common in adhesive tape applications.

Without a specific information base, it’s not easy to assign an adhesion mechanism to each type of adhesive, especially as several mechanisms can be combined in the same bonding process. However, in the light of these explanations, it is important to consider in the context of this article adhesives that fuse with the material to be bonded (e.g. TPE glues) and those that establish an adhesive bridge between the surfaces to be bonded (e.g. silicone sealants).

Warning: it is very difficult to know the exact composition of TPE and silicone bonding products, mainly because of industrial secrecy. Information on this point is therefore provided without guarantee.

IV – TPE BONDING

1 – General issues

TPEs used in the manufacture of lovedolls have two important characteristics for bonding: the relative fragility of the polymer network, and the presence of an oily filler.

These two characteristics limit the types of adhesives that can be used, but also make it possible to apply specific solvent fusion-bonding processes.

2 – Specific solvent-based adhesives (TPE glues)

These are bonding products incorporating a solvent which facilitates adhesion and which, as it evaporates, allows the bonding zone to solidify. These products are often referred to as “TPE glue”, not to be confused with cyanocrylate-based glues and superglues, which are the subject of the next paragraph.

Bonding is semi-instantaneous, requiring wound edges to be held under pressure for a few minutes, if possible extended for an hour or two depending on the extent and depth of the bonded areas.

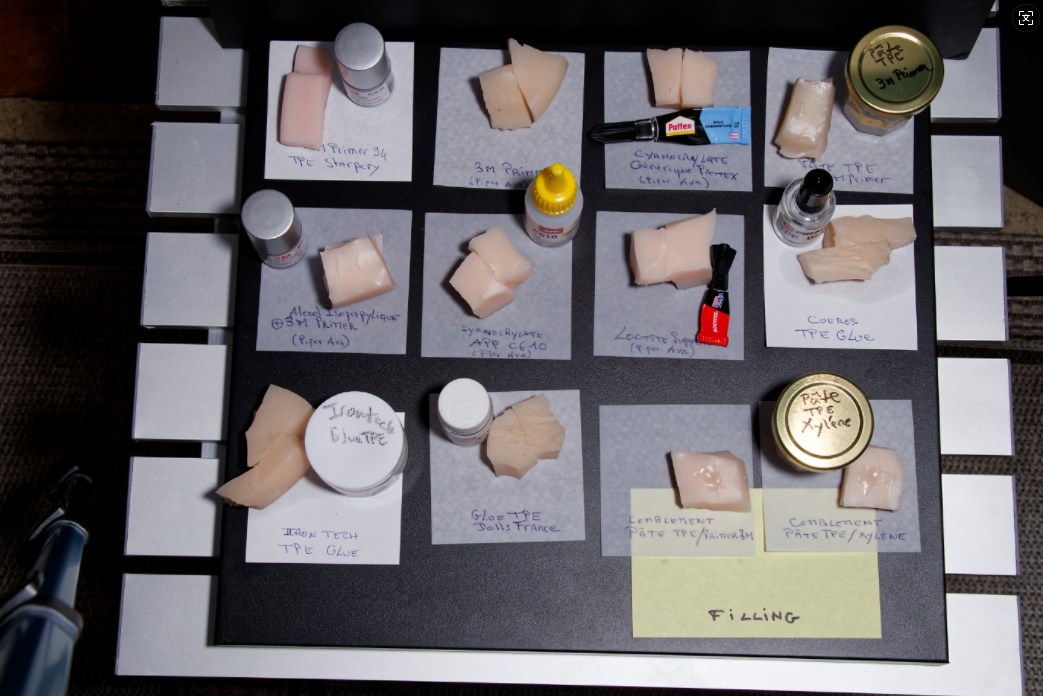

Products tested :

- TPE glue marketed by DollsFrance.

Please note that Dolls France’s TPE glue is limited to certain doll brands (WMdolls, SEdoll, ORdoll, YLdoll (Yourdoll), Jellynew, Dollsfrance and RLSD).

- TPE Sex Doll Repair Glue marketed by Coeros.

- IronTech TPE repair glue (supplied by Coeros for testing, but not sold on its website).

3 – Cyanocrylate glues

Cyanocrylate adhesives are instant bonding products used in many fields, notably in medicine for the repair of certain wounds. They work by polymerization at room temperature. Some of these adhesives are enriched with additives such as rubber, making them more flexible. In fact, the main drawback of these adhesives is the hardening of the bonding zone. An example of an enriched adhesive is Loctite’s Super Glue 3 power Gel®.

The advantages of cyanocrylate adhesives are numerous:

- Precision bonding, achieved very quickly;

- No visible thickness between wound edges;

- Preservation of the TPE’s flexibility;

- Perfect resistance to stretching.

In addition, with rubber-enriched cyanocrylate adhesives, there is no visible or palpable hardening, either on the surface or at depth.

Please refer to the article published on this subject: https://uploadnow.io/s/bed04d2d-6e5f-4c7e-84cf-0326db981e70

This article includes a sample test of the Loctite adhesive mentioned above.

There are other cyanocrylate adhesives designed for bonding difficult plastics and polymers, such as Wurth’s Plastobond or APP (Auto-Plast Produkt) C610 medium viscosity.

Products tested :

- Cyanocrylate glue Pattex generic

- Loctite SuperGlue3 rubber-enriched cyanocrylate adhesive

- AutoPlast Produkt APP C610 cyanocrylate adhesive

4 – Primer-bonding products: 3M Primer 94

This product is not originally intended for bonding plastics, but for preparing them prior to application of a 3M adhesive film. As such, it is neither designed nor suitable for bonding TPE. However, we find on TDF some explanations to the effect that 3M94 primer can melt TPE and even produce an adhesive, filling TPE paste https://dollforum.com/forum/viewtopic.php?p=2628057#p2628057

We therefore decided to include this primer in the list of products tested.

5 – TPE pastes

These are TPEs melted in a solvent, which are used more as a filler, but which we tested as a bonding agent.

Products tested :

- TPE paste + xylene

- TPE paste + 3M Primer 94

NB : Coeros TPE paste had not supplied

6 – As a reminder: heat welding bonding

The principles of plastic welding can be found in the Wikipedia entry on the subject: https://fr.wikipedia.org/wiki/Soudage_de_plastiques

The only technique available to a DO is the use of a pre-heated piece of steel, soldering iron or spatula. Placed in contact with the wound edges, this piece melts the TPE. The wound must be closed immediately before the TPE cools and solidifies.

This operation is often followed by smoothing the scar with a smoothing iron or heated spoon.

V – BONDING SILICONES

1 – General issues

Silicones used in the manufacture of lovedolls are a more compact and less fragile materials than TPEs. As a result, they are less sensitive to solvents, and not at all to heat up to very high values.

Their main characteristic for bonding is their low surface energy. Schematically, this is a measure of the way in which the molecules of one material are attracted to each other and to the molecules of other materials. Surface energy is a good measure of how easy (high energy) or difficult (low energy) it is to adhere to a surface. This notion is close to that of surface tension, or interface energy.

If it is difficult to adhere to a material because of its low surface energy, there are various ways of increasing the surface energy of a material, thus improving bonding ability. One of these is the application of a specific primer to the parts to be bonded.

However, it should be noted that surface energy only comes into play for non-polymerized bonding products, which form a separate bonding zone from the silicone bonded parts. Only cyanocrylate adhesives are concerned. In fact, polymerized products – silicone sealants and liquid silicones – are based on an anchoring mechanism between two polymers of similar composition and structure, like a chemical weld.

2 – Silicone sealant-glues

Silicone sealant-glue are versatile, water-resistant polymers whose main ingredient is silica, or more precisely polysiloxane, the basic component of polymerized silicones. The term “sealant” is used to designate products that are used in building work as sealants. Their strong adhesion to all kinds of materials, and to polymerized silicones in particular, makes them the products of choice for bonding silicone doll wounds. What’s more, they polymerize at room temperature to form a soft, elastic seal. On the other hand, they have a certain thickness, which varies from product to product, and which may remain visible at scar level, especially as they are generally translucent.

The difference between silicone glue and silicone sealant is sometimes described: a priori, there is no difference, or only a marginal one, in the addition of additives, adhesives or colorants. I’ve noted that silicone sealant- glue (Xycolo) is a little more fluid than DIY silicone putty, but basically it’s the same product.

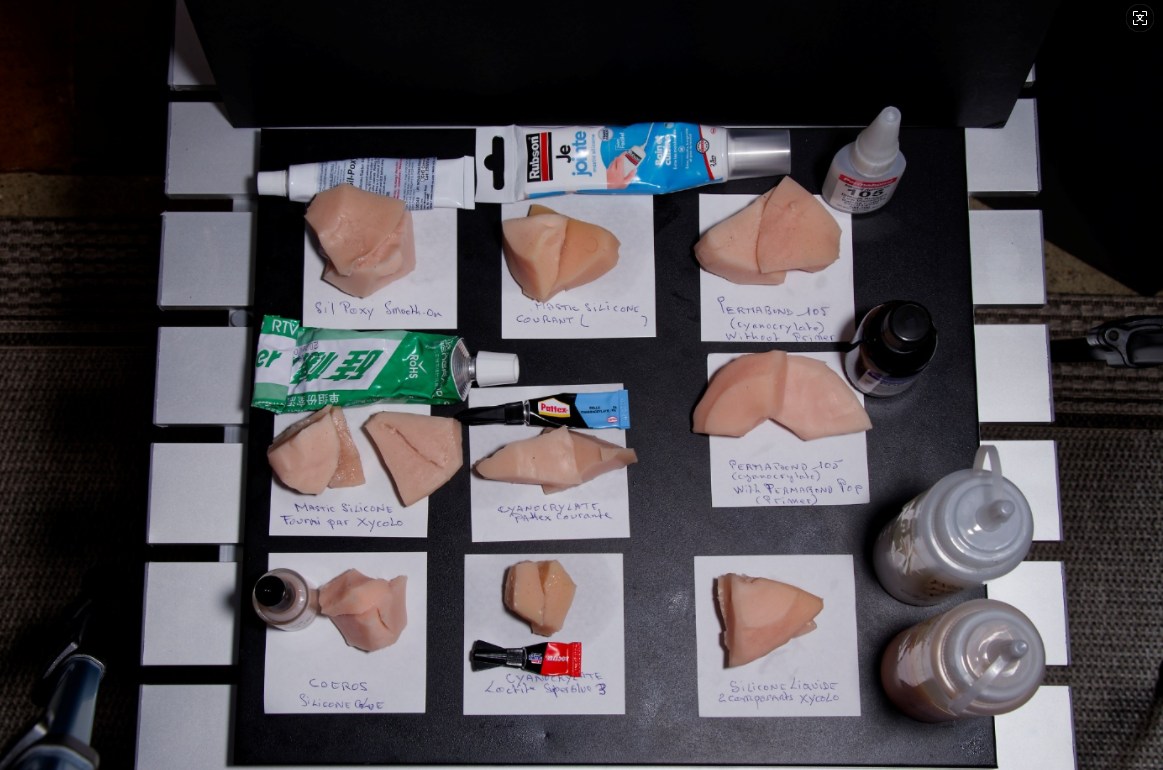

Products tested :

- Xycolo sealant-glue

- Generic silicone sealant Rubson

3 – Generic cyanocrylate adhesives

These are the adhesives you’ll find in the shops, in liquid or gel form. Some are enriched with rubber, giving them an extra degree of flexibility.

It is often said that the low surface energy of these adhesives makes them unsuitable for use on silicones. We wanted to carry out tests to see whether, in the context of bonding wounds to lovedolls, this hypothesis is valid.

Products tested :

- Pattex multipurpose liquid cyanocrylate adhesive

- Loctite Super Glue-3 Power Gel rubber-enriched cyanocrylate adhesive.

4 – Specific cyanocrylate glues applied with or without primer

These glues are specifically designed for bonding difficult plastics and polymers. We have chosen two cyanocrylate glues, Auto-Plast Produkt APP C610 and Permabond 105. Permabond offers a POP Primer (PolyOlefine Primer) for application to low surface energy materials such as silicones, prior to bonding with cyanocrylate glue. A minimum of two hours of primer action is recommended before bonding.

Products tested :

- Auto-Plast Produkt APP C610

- Permabond 105 only

- Primer Permabond Pop (=> 2 hours) + Bonding Permabond 105.

5 – Sil-Poxy and single-component diluted liquid silicones

Warning: these products are sometimes called “glues”, but they are not cyanocrylate-based glues or superglues.

Generally speaking, they are silicone, i.e. polysiloxane, diluted in a solvent, which polymerizes at room temperature as the solvent evaporates. The difference with silicone sealants is that silicone sealants are polymers that solidify on contact with air, whereas liquid silicones are not polymerized, so their polymerization is secondary and occures during bonding. This being the case, the result is very similar, with all the parts and the bonding material together forming a solidar, polymerized whole.

On the other hand, there are liquid silicones specifically tinted for lovedolls, such as those from IronTech marketed by the Coeros company, or the one supplied by the Xycolo manufacturer, whereas there are no flesh-colored silicone sealants (the colors available are those used in the building industry: gray, brown, black…).

Products tested :

- Silicone Sex Doll Repair Glue / Sil-poxy (COEROS)

- Sil-Poxy Silicone Rubber Adhesive (Smooth-On)

- IronTech colored single-component liquid silicone (marketed by Coeros)

6 – Two-component liquid silicones

The components are a non-self-curing liquid silicone on the one hand, and a polymerising agent on the other. Mixing the two components produces a semi-fast-curing silicone, which solidifies in a few hours. Products of this type are available for the manufacture of silicone molds, in various shades or with dyes. Lovedolls manufacturers like Xycolo also offer to supply a liquid silicone kit in the same shade as the doll, on request.

Although these products can be used to bond wounds without loss of substance, they are generally more suitable for filling large wounds or for remodeling (see below).

Products tested :

- Two-component Xycolo liquid silicone

- Non-specific liquid silicone test (SANAA silicone mold kit) and specific DecoRom colorants.

VI – BONDING AND RESISTANCE TESTS

Tests were carried out on uncalibrated samples of TPE from various origins (WMDolls, Irontech, SEDoll and undetermined) and silicone (Xycolo).

Two types of test were carried out:

- Simple bonding test: bonding of two samples, with the parts held under pressure for a few hours, at room temperature (20-24°C). Visual examination and manual stretching test: welding or juxtaposition, extent and strength of bonding, examination of edges (dryness or persistence of liquid or gel);

- Resistance test, by suspension of a 200 gr. This weight is sufficient to test an average resistance and a good bonding quality. It corresponds to the current stretchings of a doll. For extreme stretching corresponding to trauma, a higher weight would have to be selected.

1 – TPEs

Summary table of test results – TPEs

Product | Accuracy | Setting time | Appearance | Stretch Manual | Resistance test (c) |

Cyanocrylate glues | |||||

Pattex generic | PiperDoll TPE | < 1mn | Juxtaposition, hard | OK | OK |

Loctite SuperGlue3 | TPE PiperDoll | < 1mn | Welding, flexible | OK | OK |

APP C 610 |

|

|

|

|

|

Specific solvent-based TPE glues | |||||

DollsFrance TPE glue |

| ~10 mn(a) | Welding, flexible | OK | OK |

TPE glue Coeros |

| ~10 mn(a) | Welding, soft | OK | OK |

IronTech TPE glue |

| ~10 mn(a) | Welding, soft | OK | OK |

Other products | |||||

Primer 3M94 | Starpery TPE |

| Limited bonding | KO | KO <10 s |

Primer 3M94 | PiperDoll TPE |

| No bonding | KO | KO |

AP(b)+Primer 3M94 | TPE PiperDoll |

|

|

|

|

TPE+Primer3M94 paste | TPE PiperDoll |

| Limited bonding | OK | KO<30 s |

(a) Minimum time. Complete weld is obtained after a few hours

(b) Isopropyl alcohol

(c) OK = good resistance, with no tearing or peeling, after approx. one hour’s suspension.

Details of 3M 94 Primer tests

1sttest: inconclusive result. I didn’t even have to carry out the 200g test, as the bond gave way when the two parts were stretched slightly by hand.

2nd test: after re-reading Wheezer’s recommendations on TDF https://dollforum.com/forum/viewtopic.php?p=1765777#p1765777, I decided to repeat the test by first applying isopropyl alcohol to both sides before gluing with Primer 94.

Adhesion strength is better, but the bond is not of good quality, and doesn’t pass the weight test.

All in all, and contrary to the tangible results obtained by other DOs on TDF, we did not achieve a satisfactory result with this technique.

The author of the topic on TDF specifies that the TPEs he processed were those of “dolls from WM, Kimber, JellyDoll, JellyNew, TPE sex toys and several other dolls of unknown type.”

It’s possible that the TPE (Piper Doll) in our samples is resistant to this product. We wanted to repeat the test with Starpery TPE. The result was only slightly better.

To continue with this product and these tests with surprising results, we added a test using this time a TPE paste obtained by diluting a fragment of TPE from the same sample in Primer 3M94. This time, the bond proved satisfactory, but did not withstand the 200 g test weight for very long.

The contrasting results of these tests are difficult to interpret , but we have to publish them.

2 – Silicone

Note that Xycolo silicone is “organic”. It’s a fairly firm silicone, but of relatively low density (it’s the least heavy of the silicones used by Xycolo to make its dolls).

Summary of test results – Silicone

Product | Precision | Setting time | Appearance | Stretch Manual | Resistance test (c) |

Cyanocrylate adhesives | |||||

Pattex generic | (a) | < 1mn | Juxtaposition, hard, limited bonding | KO(b) | OK(b) |

Loctite SuperGlue3 | (a) | < 1mn | Juxtaposition, hard, limited bonding | KO(b) | OK(b) |

Pemabond 105 | (a) | <1 mn | Juxtaposition, hard | OK | OK |

Pemabond 105+Primer Pop(d) | (a) | <1 mn | Juxtaposition+welding(d), hard | OK | OK |

Silicone sealants | |||||

Generic sealant(e) | (a) | ~1h | Juxtaposition, thickness | OK | OK |

Glue putty Xycolo |

| ~1h | Adjoining, thickness+ OK | OK | OK |

Sil-poxy and single-component liquid silicones | |||||

Sil-poxy Smooth-On | (a) | ~1h | Welding, flexible | OK | OK |

Silicone Glue Coeros | (a) | ~1h | Welding, flexible | OK | OK |

Two-component liquid silicones | |||||

Xycolo(f) | (a) | ~3h | Welding, flexible | OK | OK |

(a) Organic silicone Xycolo

(b) Withstands 200 gr but yields fairly easily to manual stretching

(c) OK = good resistance, without tearing or peeling, after about an hour’s suspension

(d) The combination of primer and sealant seems to favor partial welding.

(e) Transparent silicone bathroom sealant in tube (Rubson)

Terminology:

- Juxtaposition: there is no weld, the two samples are juxtaposed, separated and adhered by a sticky layer.

- Welded: the two samples are welded, with no visible intermediate layer

- Hard: the adhesive interlayer is hard to the touch

VII – SPECIAL CASES

1 – Wound filling operations

These are wounds with substantial loss of substance, which cannot be closed without filling the space between the edges. Filling involves adding material to compensate for localized loss of material.

Any filling operation must, of course, incorporate an adhesion mechanism.

The main problem with filling on TPEs or silicone is the color of the filler, which generally does not match that of the headstock to be repaired.

1.1- TPEs

1.1.1 – Filling with a cold self-curing liquid TPE paste. There are various products of this type, such as the “TPE Sex Doll Paste” marketed by Coeros.

Numerous TDF topics or YouTube videos mention the possibility of making your own filling paste from TPE fragments and a solvent, usually xylene or 3M primer94.

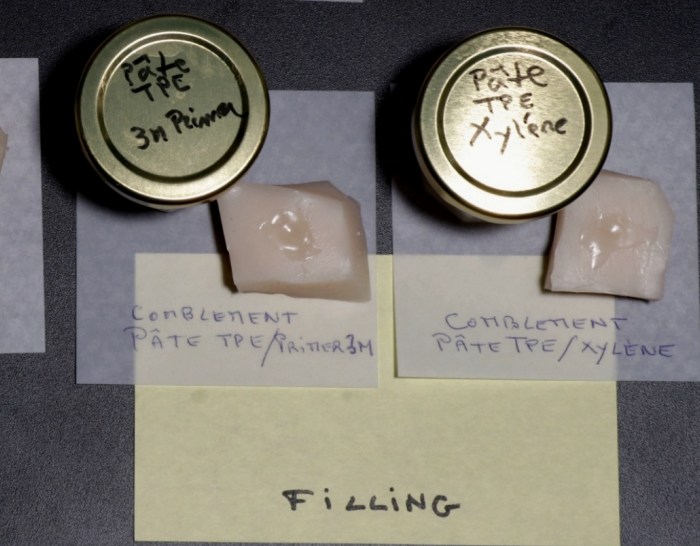

Products tested :

- TPE paste made with 3M Primer

- TPE paste made with xylene

NB: Coeros TPE paste is the only industrial product of this type that we found. Not supplied, to be reviewed at a later date for further testing.

Results of filling tests carried out

Filling a small experimental wound is easy to perform. However, there are two major drawbacks to these products:

- They are liquid and tend to run as soon as the wound is not strictly horizontal. Run-off can easily be removed with acetone, but this does not solve the problem of product retention during polymerization;

- They shrink as they dry, requiring a minimum of three applications to achieve a flush result.

1.1.2 – Filling with melted TPE by heat exposure of TPE fragments placed inside the wound. An example of a demonstration video:

These techniques may be preferable to the previous ones, as they do not have the same disadvantages. In particular, they allow for very quick setting. However, repairing TPE using a tool or hot air requires a correct level of skill, as there is a significant risk of secondary damage.

1.2 – Silicones

- Silicone sealants: good for bonding, but not so good for filling: too hard, not very adhesive over time in areas subject to stretching, and often form a translucent, unattractive block.

- Two-component liquid silicones polymerizing at room temperature.

Products tested :

- Xycolo two-component silicone

- Liquid silicone: SANAA silicone mold kit. It was interesting, although I hadn’t read anything on the subject, to try using commercially available two-component silicone to make epoxy resin molds. These products can be tinted with special dyes, making them theoretically attractive for repairing silicone dolls.

Xycolo (left) Sanaa (right)

Same overall findings as for TPE filling, with two major drawbacks:

- They are liquid and tend to run as soon as the wound is not strictly horizontal. Run-off can easily be removed with acetone, but this does not solve the problem of product retention during polymerization;

- They shrink as they dry, requiring a minimum of three applications to achieve a flush result.

With this in mind, the question arose of using silicone selant for filling, after dyeing with the aforementioned silicone colorants. Standard silicone putty (Rubson) and DecoRom liquid silicone dyes were used.

The results are quite convincing: good quality filling, firm adhesion to wound edges, no shrinkage after drying (a single application may suffice). In the test example, the silicone shade was not optimal, but an adjustment with the shades provided. This first experiment should be continued using different sealants and colorant combinations to get closer to the sample shade and achieve a better final appearance.

2 – Gluing eyelashes and nails

This involves gluing a synthetic material, usually plastic, onto eyelids or fingers in TPE or silicone. You can use :

- The specific latex- or rubber-enriched glues supplied with these accessories for human use, which have the advantage of flexibility and are easy to remove;

- Cyanocrylate glues, which are very strong, but not flexible and difficult to remove. Rubber-enriched cyanocrylate adhesives are more flexible;

The use of 3M94 primer has been mentioned on TDF, but no opinion will be given on this product in this application.

If the false nail is glued on top of the original nails, various adhesives can be used, with those intended for gluing false nails having the advantage of allowing more or less easy removal, generally with hot water. There are also double-sided adhesive pads supplied with some false nail kits.

3 – Gluing the “small body” of silicone dolls

The “small body” or deep layer of silicone dolls, which surrounds their skeleton and helps lighten their final weight, is made of polyurethane foam. When this layer is affected by an accidental or deep surgical wound, neoprene glue can be used for bonding.

4 – Remodeling operations

The reshaping of a deformed area (breasts, buttocks, thighs, etc.) is achieved by injecting a wide variety of products. Some are products used for filling (single- or two-component liquid silicone). See our article on remodeling the breasts of a silicone doll.

Others range from air to commercially available gels (aloe vera, ultrasound gel…). These techniques will not be developed further in this article.

VIII – CONCLUSIONS AND RECOMMENDATIONS

General issues

When bonding TPEs and silicones, a few rules of good practice should be followed to ensure the effectiveness and safety of the operation:

- Know exactly what material you’re dealing with (beware of mixed dolls with silicone heads and TPE bodies!);

- Carefully examine the area to be repaired, and in particular determine whether there is any loss of substance (filling techniques) or not (bonding techniques);

- Prepare the areas to be bonded: careful cleaning, stain removal if necessary, protection of adjacent areas, application of primer if required;

- Bonding must be carried out in compliance with the manufacturer’s and/or dealer’s instructions concerning: setting time (restraint is often necessary, and must be provided before applying the adhesive), complete drying time (which may be longer than the setting time);

- Remove any burrs or excess with a glue solvent that is safe for the doll;

- Check the effectiveness of the bonding, completing if necessary before returning to everyday life.

Special issues

TPE

All adhesive products tested proved effective (excluding the specific case of Primer 3M94). Cyanacrylate adhesives in particular can be used. The choice will therefore depend on the bonding method, the setting and drying time, the final appearance of the wound and the expected tactile sensation. If the bonded area is subject to significant stretching, I would recommend a chemical welding product, i.e. a specific solvent-based TPE glue.

Silicone

Generic cyanoacrylate glues should not be used. Reinforced cyanoacrylate adhesives, especially when used with a specific primer, are effective.

Silicone adhesive joints are very effective, but it is important to control their thickness and transparency. On this last point, the study has opened up a new avenue, namely the use of silicone adhesive joints combined with a colorant to create a paste similar in color to that of the doll.

Single-component adhesives sil-poxy type have proven to be very effective, with results similar to welding.

Finally, a pleasant surprise was the two-component liquid silicone supplied by a manufacturer for breast remodeling, which proved to be very effective for bonding.

Please note: we saw little difference between TPE and silicone brands. However, the variety of test samples was limited in this study. As a precaution, I would therefore recommend testing on a sample or on an inconspicuous area of the doll before undertaking any major bonding or filling work.

We hope that this article sheds some light, albeit partial and still to be completed, on the various products that can be used to bond and fill wounds affecting TPE or silicone dolls. This study was not intended to test all existing products. Tests on other bonding and filling products will be added to this publication at a later date.

NOTA BENE

The products sold by Coeros and the IronTech TPE glue were kindly supplied to me by Coeros. Many thanks to them.

Xycolo’s liquid silicone was supplied to me free of charge by the manufacturer, as part of a breast reshaping operation.

The other products were purchased by the author.

This work was carried out without any methodological or editorial constraints.

Biographic note

Victor

The author of this study is a French DO (Vicvic on TDF, Victor or Victor123 on European forums). Currently retired after a career in the medical field, he owns around ten large TPE and silicone dolls, as well as numerous small littel dolls, BJD, Smartdoll, and other dolls. His life with dolls began with a TPE doll in 2020. He loves photographing them and staging them, publishing on forums, on his Facebook page*, and on his YouTube channel**. At the same time, he is interested in all topics related to dolls and humans’ passion for them, whether historical, psychological, anthropological, medical, and, of course, technical. His favorite technical areas are removing stains, wound repair, surgery, standing and suspension, as well as all techniques that allow him to stage and animate the dolls. He readily admits that he is not an expert in makeup or sexual issues related to love dolls.

If you would like to contact him, please do so via his privacy message on the forums.

- On TDF: https://dollforum.com/forum/ucp.php?i=pm&mode=compose&u=530319

- https://www.facebook.com/profile.php?id=100081884907686&sk=photos

- www.youtube.com/@klausvictor3038